Optimized processes & resources

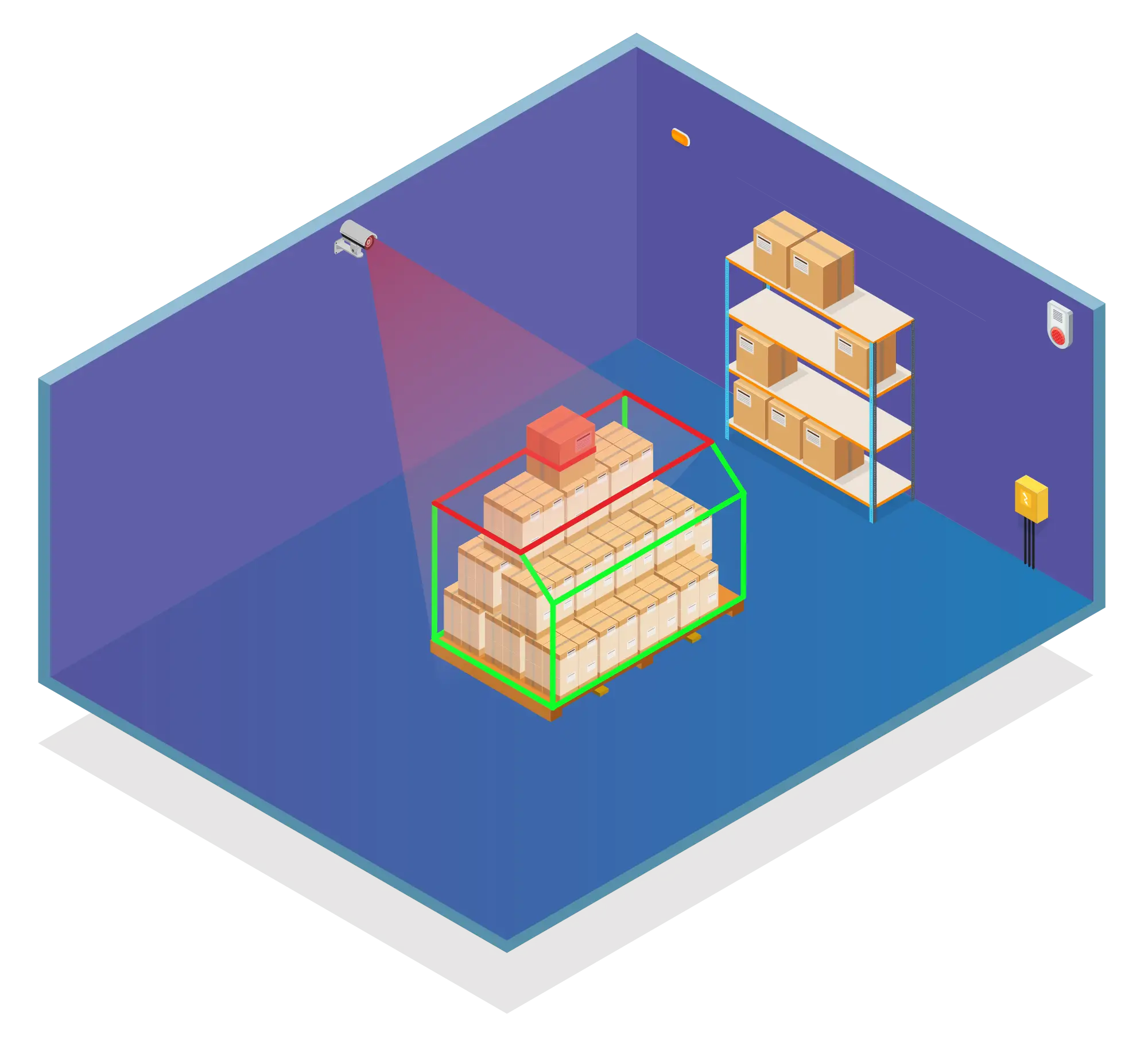

With IKARA CargoFit, cargo pallets can be custom-built and prepared for air freight. Through 3D measurement, packages are tracked in real-time and checked for fit within predefined contours. Pre-existing contours can also be verified. Visual feedback indicates whether the package is too large.

Ensure precise invoicing and prevent service interruptions with the computer vision-based ULD measurement. Optimize the efficient use of cargo space. Our computer vision-based ULD measurement was developed in collaboration with experts from Lufthansa Industry Solutions and addresses critical issues for logistics companies.

How it works

Precise depth cameras mounted on a framework capture a detailed point cloud of the pallet to create an accurate 3D representation of the goods. This data is then analyzed by artificial intelligence, which, using IKARA’s proprietary optimization algorithms, determines the exact shape of the pallet.

Based on this analysis, the system calculates the volume and dimensions of the goods, which can then be compared to the specified ULD requirements. This allows for early detection of discrepancies between the actual and planned shape, enabling adjustments to be made and ensuring efficient use of cargo space.

Your advantages at a glance

Our expertise in

numbers and votes

Specialists

Years

Servers used

Analyzed cameras

Other providers with glossy brochures, they go around for two years, don’t get it right, and IKARA is up and running after three weeks.

Manuel Peter - Head of Department REWE Logistics

Andere Anbieter mit Hochglanzbroschüren, macht zwei Jahre lang rum, kriegt es nicht hin, und IKARA ist nach drei Wochen am Start.

Manuel Peter - Abteilungsleiter REWE Logistik

I’ve been waiting for this for decades. You inspire me.

Filip Pax - Director Process Engineering DHL Aviation

Darauf habe ich seit Jahrzehnten gewartet. Sie begeistern mich.

Filip Pax - Director Process Engineering DHL Aviation

IKARA has successfully implemented our strategically important lighthouse project of OEPE time measurement in McDrive Digital 21 with excellent results.

Christian Schröder - Senior Director Operations McDonald’s Deutschland LLC

IKARA hat unser strategisch wichtiges Leuchtturmprojekt der OEPE-Zeitmessung in McDrive Digital 21 erfolgreich und mit hervorragenden Ergebnissen umgesetzt.

Christian Schröder - Senior Director Operations McDonald’s Deutschland LLC

IKARA is one of the leading independent software vendors in the DACH region, specializing in the creation of enterprise software.

Volker Meschonat - Smart Cities NVIDIA

IKARA ist einer der führenden Independent Software Vendors in der DACH-Region, der sich auf die Erstellung von Unternehmenssoftware spezialisiert hat.

Volker Meschonat - Smart Cities NVIDIA

Deployment at

key locations in the industry

System requirements

for the installation

Linux-Requirements

The installation requires a Linux distribution (e.g., Ubuntu 18.04 or newer, Linux Mint 18 or newer) with the following installed packages:

- Docker Engine (20.10.x or newer)

- Docker Compose (1.28.0 or newer)

- Nvidia Container Toolkit (1.5.0 or newer)

Server-Requirements

- CPU: 8-Core-CPU (e.g. Intel Core i7-9700K)

- RAM: 32 GB

- GPU: Nvidia RTX4000 or RTXA4000 (suitable for 4 streams)

If you wish, you can purchase a suitable server with the installed software directly from us.